Steve_Reeves

New Member

Hi all,

I'm interested in building my first project build using the PICAXE EXPERIMENTER BOARD (AXE090), and would be intersted in suggestions on programing the 18X chip.

My intension is to use a piezo pressure transducer,input to the ADC,and output to a two digit LCD diplay.

The object of the exercise it to moniter boost pressure, to a turbo diesel engine, diplaying turbo boost pressure.

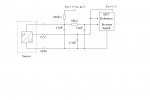

The Transducer is a automotive device with a 5v supply, ground, and signal out. The schematic drawing, i will post shortly.

Help would be much appecciated.

Regard's

Steve.

I'm interested in building my first project build using the PICAXE EXPERIMENTER BOARD (AXE090), and would be intersted in suggestions on programing the 18X chip.

My intension is to use a piezo pressure transducer,input to the ADC,and output to a two digit LCD diplay.

The object of the exercise it to moniter boost pressure, to a turbo diesel engine, diplaying turbo boost pressure.

The Transducer is a automotive device with a 5v supply, ground, and signal out. The schematic drawing, i will post shortly.

Help would be much appecciated.

Regard's

Steve.