Pongo

Senior Member

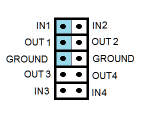

Does anyone have a good scheme for the download connection for programming multiple picaxes on a board? I'm going to have 4x 08M2's on the board, I don't mind duplicating the download circuits but I'm wondering if there's a way to simplify the switching of the PC connection. For instance maybe I can OR the serial outs and use a dip switch to select the serial in.

(I'm not using the serial in/out in the application.)

(I'm not using the serial in/out in the application.)