Andres Rodriguez

New Member

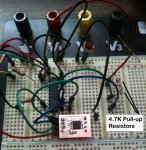

With the attached schematic and the code listed below, I write two bytes (values 0 and 1) repeteadly. When I read the data I get 255. I found a thread initiated by another member with the same problem and did no see a solution.

The memory chip is FW24W256 from RAMTRON

http://www.ramtron.com/files/datasheets/FM24W256_ds.pdf

The memory chip is FW24W256 from RAMTRON

http://www.ramtron.com/files/datasheets/FM24W256_ds.pdf

Attachments

-

17.9 KB Views: 51

-

841 bytes Views: 21

Last edited by a moderator: