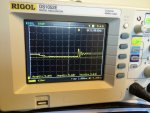

I have attempted to build a battery charger for AA size NiMH batteries and have been running into an issue. With the current setup if I connect a battery the Picaxe repeatedly resets, unless I add a 10 or 15 ohm resistor in series, then it works properly. I'm thinking when the MOSFET turns on it pulls enough current for an instant to cause the voltage to collapse. I have removed the capacitor across the battery terminals and still the same issue. Any way to get around this while still being able to supply 1A or so of charge current? With a 10 or 15 ohm resistor I can't get over about 200 milliamps to the battery because of ohm's law. I've been pondering running a regulator (3.3 volts perhaps) but if the supply voltage collapses that may not do any good. Another idea is a buck topology (rearranged to allow low-side switching) but that would require large inductors (on the order of 330 uH) if the Picaxe drove it directly. For the record this basic circuit worked on my AXE091.