Sorry for the slightly off-topic post

What do people do nowadays for making one-off PCBs?

For my current PICAXE project I'm using stripboard, but it'd be nicer to have a proper PCB.

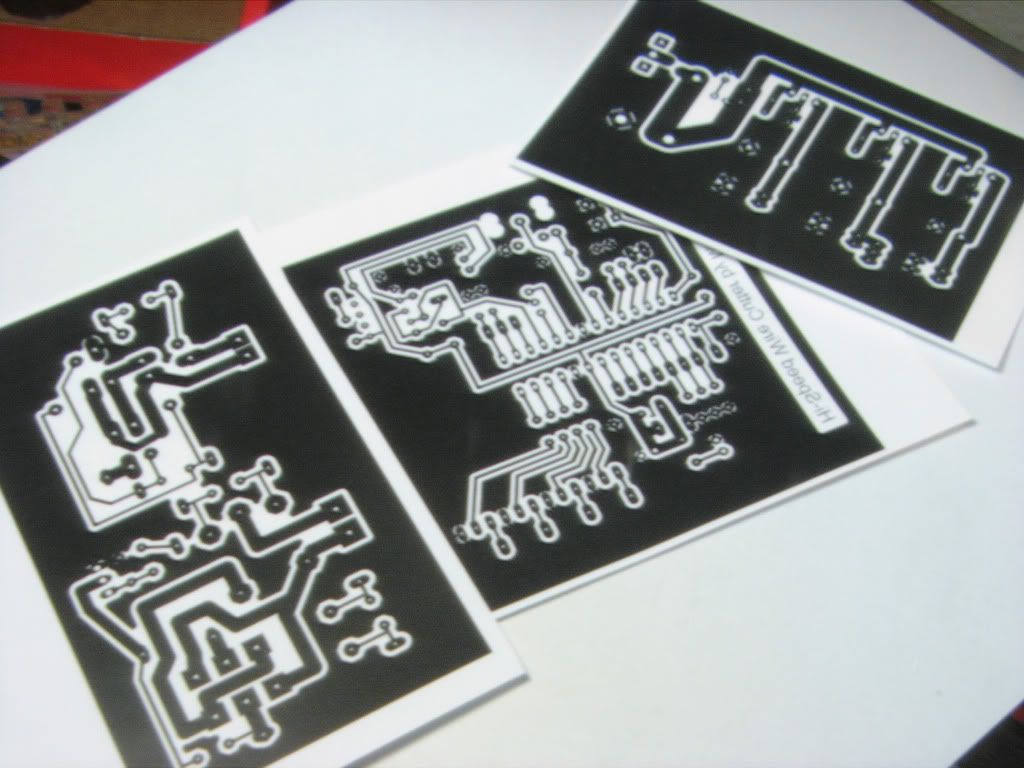

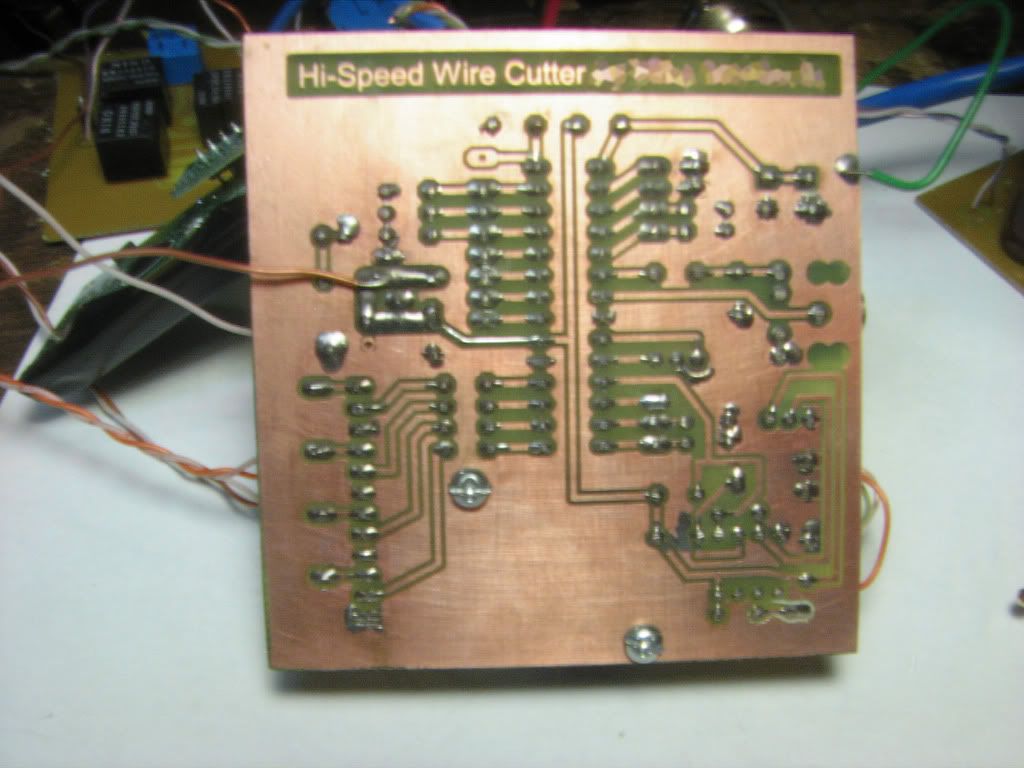

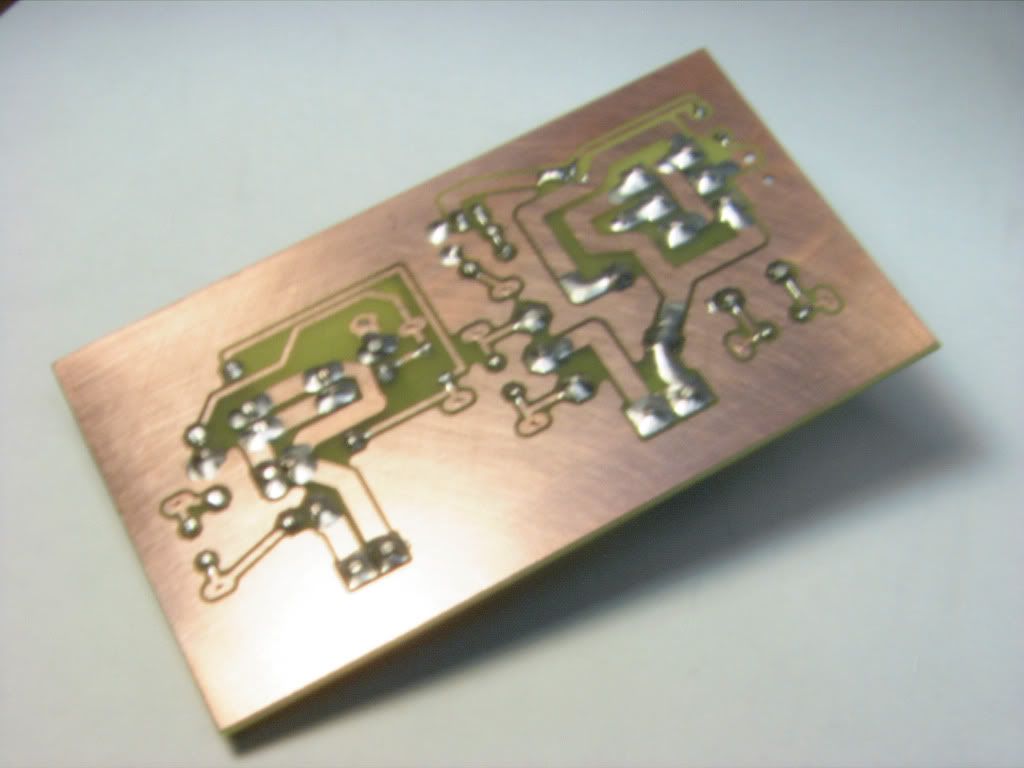

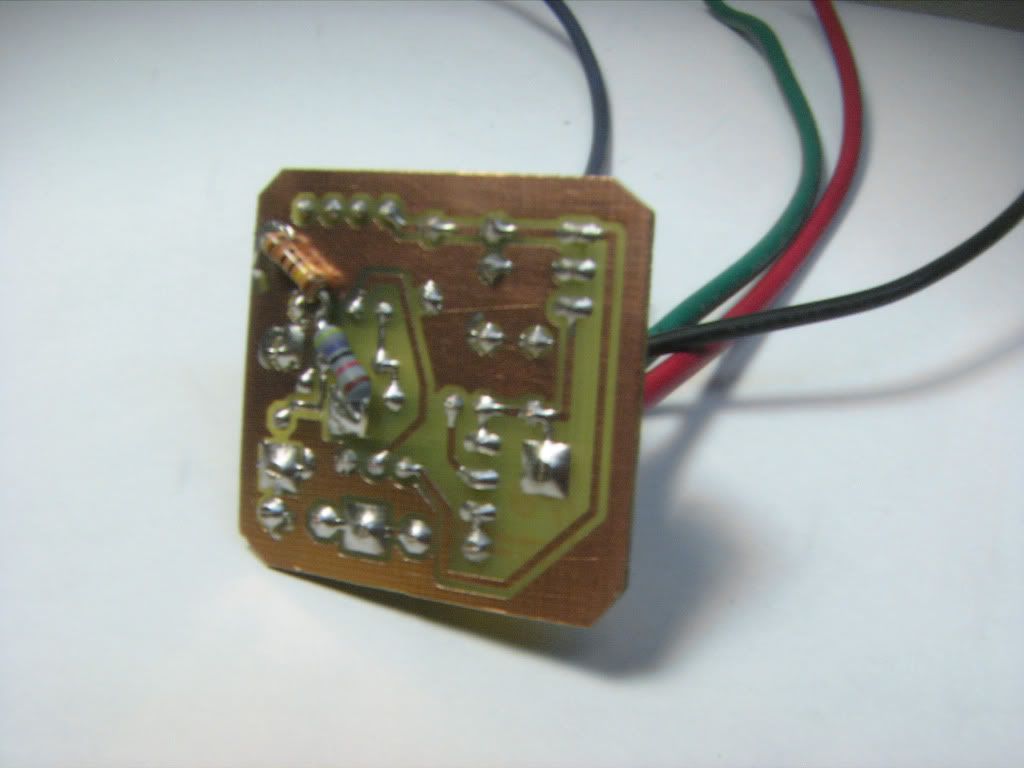

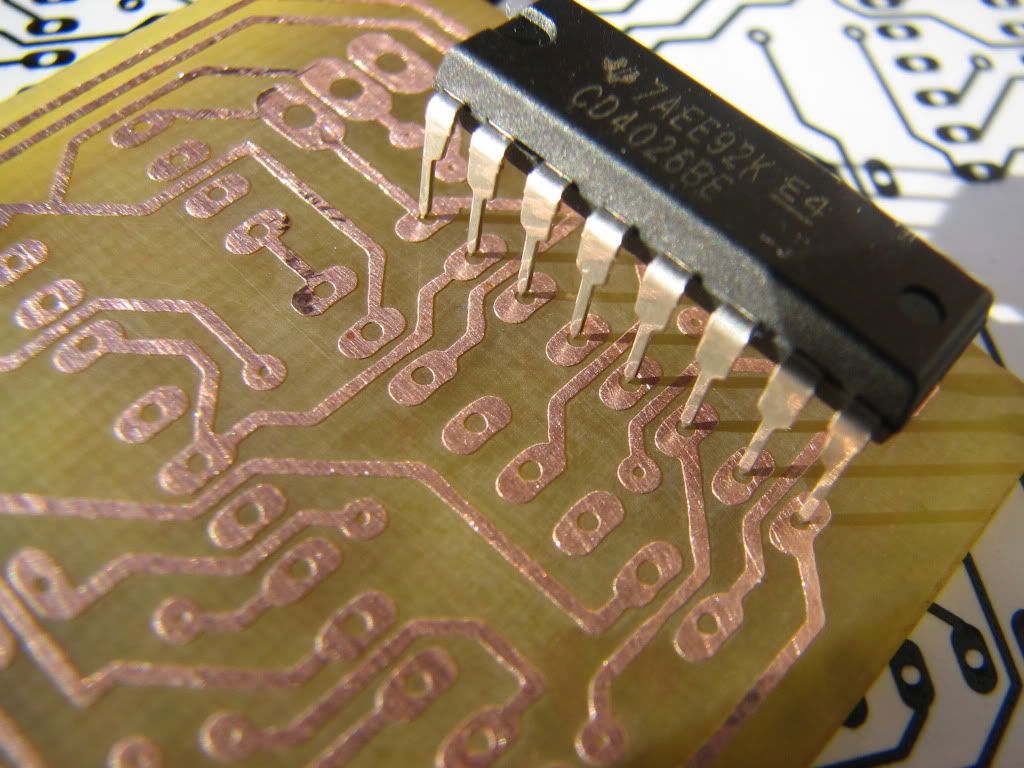

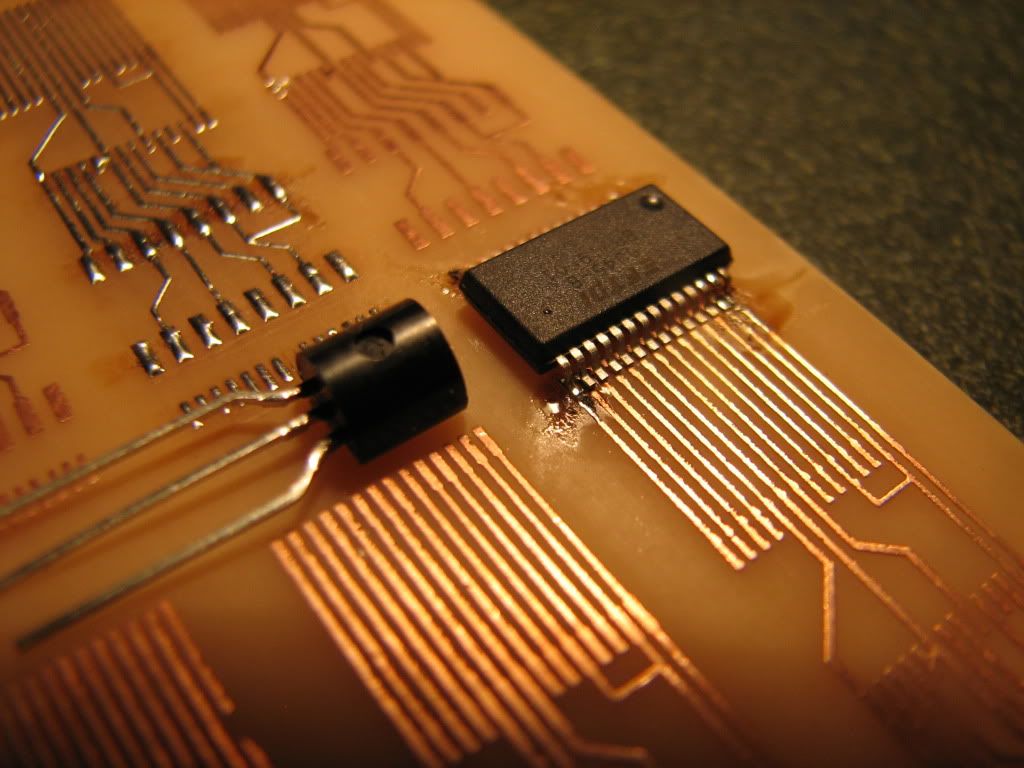

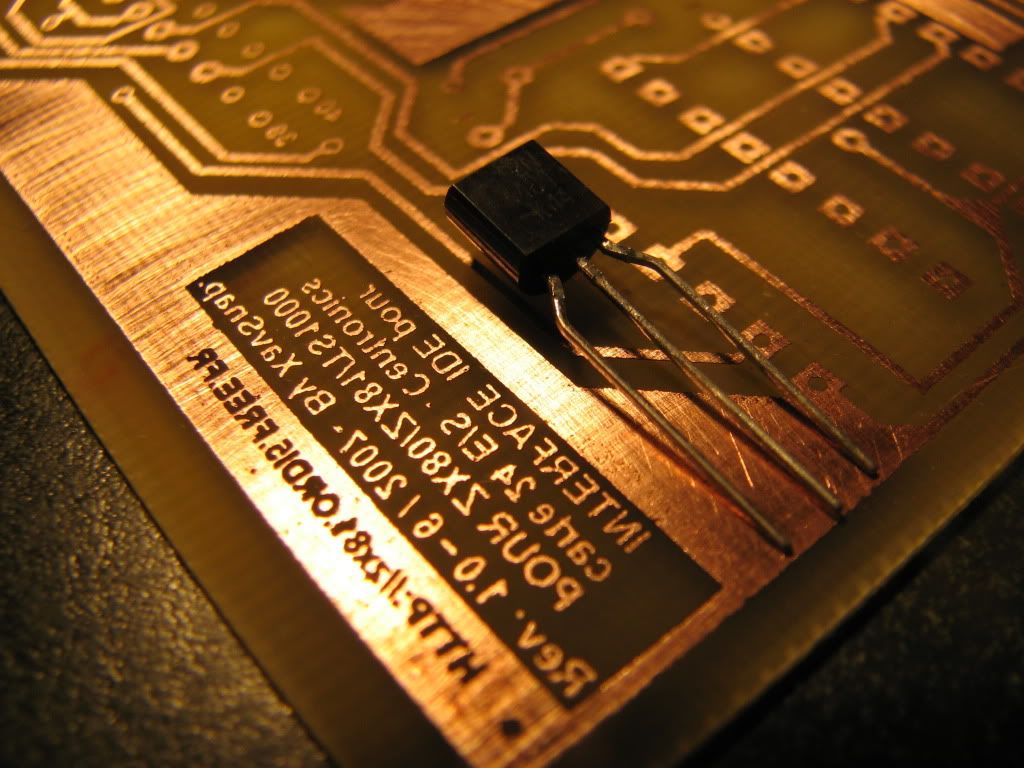

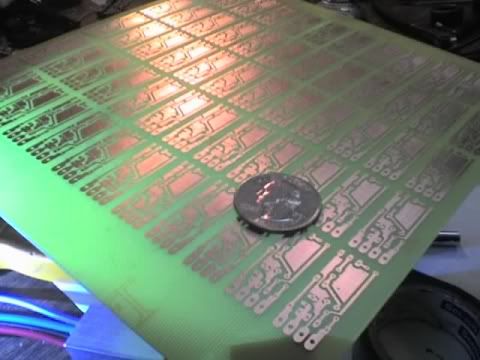

I haven't done any serious electronics for a while - about 20 years - and back then, one-off PCBs either needed a black pen and OHP acetates and UV light or self-adhesive black strips onto the bare copper. But, the world's moved on a bit since then... So, what are the current way of doing it that people find give the best results (for an affordable price).

I've seen "Press-and-Peel" transfers, laser acetates designed for PCB and so on. Are any of those better or worse than others?

What about layout design? (Back in the day you had to do it all by hand) Are there cheap/free ways of doing that?

What do people do nowadays for making one-off PCBs?

For my current PICAXE project I'm using stripboard, but it'd be nicer to have a proper PCB.

I haven't done any serious electronics for a while - about 20 years - and back then, one-off PCBs either needed a black pen and OHP acetates and UV light or self-adhesive black strips onto the bare copper. But, the world's moved on a bit since then... So, what are the current way of doing it that people find give the best results (for an affordable price).

I've seen "Press-and-Peel" transfers, laser acetates designed for PCB and so on. Are any of those better or worse than others?

What about layout design? (Back in the day you had to do it all by hand) Are there cheap/free ways of doing that?