I bought several sets of the Dick Smith breadboard wire kits before they stopped doing things but even they get a bit of a pain after a while.

The ones below are even better although not as neat on the actual breadboard.

http://www.ebay.com.au/itm/Solderless-Breadboard-Jumper-Cable-Wires-Kit-Qty75-/300553677041?pt=AU_B_I_Electrical_Test_Equipment&hash=item45fa6528f1#ht_1226wt_905

They were the ones I was actually looking for, but I suspect that for me, at least for the time being, the ones that sit flat against the breadboard and actually look a bit like the circuit diagram make it a little easier to follow.

I think I'll get some of those though. I'm sure this stuff gets easier to follow eventually.

Much of this stuff I'm learning is turned on its head a bit. Even things that everybody else finds intuitive like (and I may well have this wrong) being able to place a resistor after the thing it needs to control flow to, freak me out a little.

Even placing a component like a motor simply in series seems counter intuitive. As a kid a motor was connected one end to a battery, the other end to a battery ( realise that is simply in series). In the circuit where I'm controlling a 12 volt motor with a chip, the circuit looks a lot like I've got both motor wires connected to the same point. It works and is all correct, but I'm struggling to look at in and just "read" the circuit. I have to work out why it works every time I look at it.

That all makes it very difficult when I'm trying to learn something new like adding input from a pot, because I can never be sure if I have interpreted the diagram correctly even though it only has one component and a + and -.

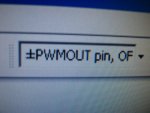

Does it matter which is + and which -, should the thing get hot enough to burn me, should I be using it as a pot or a rheostat, how do I know if I'm "resisting" enough to get a reading, why am I not getting a reading, why does debug show 255 then my reading, and flash between the two, etc etc etc etc etc

It's the first time, in as long as I can remember, that I'm learning something that seems to require a paradigm shift in the way I think rather than just learning some stuff and thinking more.