ashawthing

New Member

Hi, I am trying to create a system that will monitor temperature and adjust the speed of a fan accordingly. The fan I will be using is 12V, 6A dc.

I know how to monitor the temperature thats made easy with the use of the DS18b20 and readtemp but I am unsure exactly how to control the speed of the fan.

I've had a browse on here and it looks like I need to be using the pwmout command. Is it possible to add a variable in as on of the parameters and then have the temp reading adjust that variable up and down?

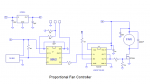

Also, could someone point me in the right direction with the circuitry I might need to power the fan?

Thanks

I know how to monitor the temperature thats made easy with the use of the DS18b20 and readtemp but I am unsure exactly how to control the speed of the fan.

I've had a browse on here and it looks like I need to be using the pwmout command. Is it possible to add a variable in as on of the parameters and then have the temp reading adjust that variable up and down?

Also, could someone point me in the right direction with the circuitry I might need to power the fan?

Thanks