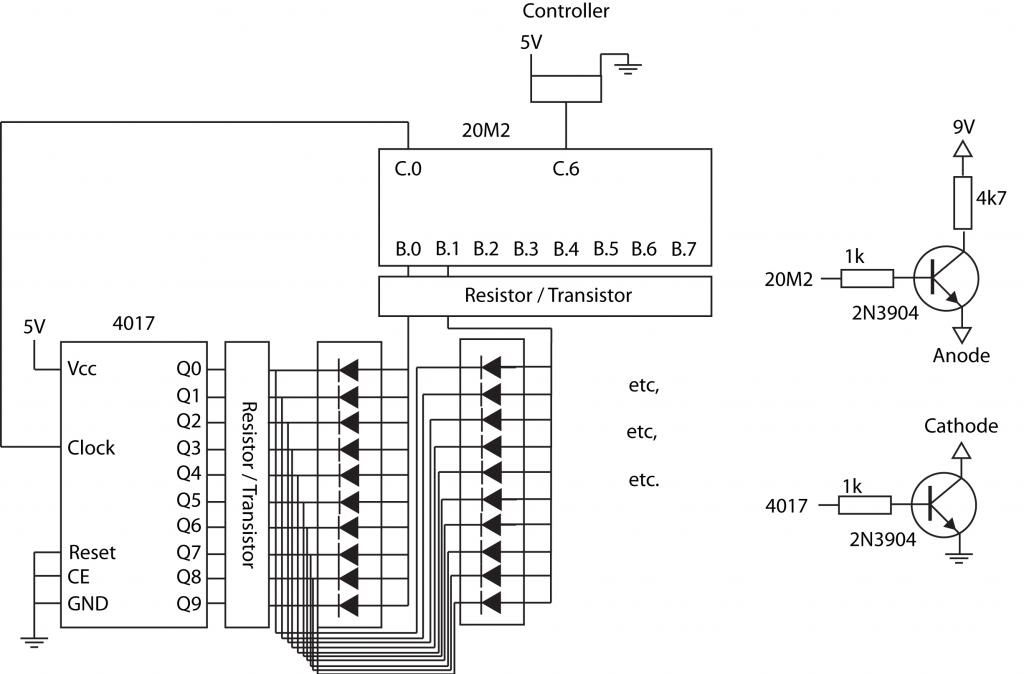

As my second PICAXE project, I'd like to work with LED bar graphs, such as these:

Possibly using LM3914 bar graph driver trips:

http://www.ti.com/lit/ds/symlink/lm3914.pdf

The idea is to use eight 10 LED bar graphs linearly lined up to show the position of a 10k potentiometer. Before I start reading up about the basic ideas and code used for this kind of thing, I'm having trouble understanding how linking the LM3914's work. I can grasp the idea of using one driver and a defined voltage ladder, but I'm not sure how they work when chained together (8 in series in my case).

I guess the initial question should be - can a PICAXE handle this kind of thing?

Thanks in advance for any tips on the chaining of IC's and further questions. I appreciate all of those who put time into helping others on this forum!

Possibly using LM3914 bar graph driver trips:

http://www.ti.com/lit/ds/symlink/lm3914.pdf

The idea is to use eight 10 LED bar graphs linearly lined up to show the position of a 10k potentiometer. Before I start reading up about the basic ideas and code used for this kind of thing, I'm having trouble understanding how linking the LM3914's work. I can grasp the idea of using one driver and a defined voltage ladder, but I'm not sure how they work when chained together (8 in series in my case).

I guess the initial question should be - can a PICAXE handle this kind of thing?

Thanks in advance for any tips on the chaining of IC's and further questions. I appreciate all of those who put time into helping others on this forum!