We have recently bought a house in the Latrobe Valley about 130kms east of Melbourne.

Does anyone have any advice re. setting up a electronics lab/workshop? I think some of the more experienced guys must have quite extensive set ups at home or work.

After spending the last 4 years in a one bedroom flat its great to have room to move.

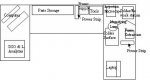

Previously I had a small desk to work on, now I have 6 meters of bench space. My benches are 600mm wide. I have 3 foot fluros above them and then more shelves above that for parts boxes. I have a lot of shelving for folders full of data sheets.

I was thinking of mounting a earthed copper rail around the edge of the benches that I could clip a anti ESD braclet lead onto. I have seen ankle type things you wear that earth the sole of the shoe to the ground but I guess that requires a special floor covering.

Theres a timber floor there at the moment. I dislike carpet because of the fibres and dust it traps. What is best in flooring re. ESD?

The bench surfaces are melamine. Is this bad for ESD?

Does anyone have any advice re. setting up a electronics lab/workshop? I think some of the more experienced guys must have quite extensive set ups at home or work.

After spending the last 4 years in a one bedroom flat its great to have room to move.

Previously I had a small desk to work on, now I have 6 meters of bench space. My benches are 600mm wide. I have 3 foot fluros above them and then more shelves above that for parts boxes. I have a lot of shelving for folders full of data sheets.

I was thinking of mounting a earthed copper rail around the edge of the benches that I could clip a anti ESD braclet lead onto. I have seen ankle type things you wear that earth the sole of the shoe to the ground but I guess that requires a special floor covering.

Theres a timber floor there at the moment. I dislike carpet because of the fibres and dust it traps. What is best in flooring re. ESD?

The bench surfaces are melamine. Is this bad for ESD?