Rickharris

Senior Member

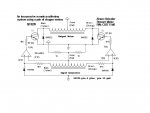

I have had a need for a rotary encoder to turn the rotations of a knob into some kind of digital signal.

I needed to know the direction of turning and how many times the knob is turned.

I have, after some experimentation, come up with the attached which seems to work OK in my lash up at present and now moves to the better engineered stage to improve the looks. The idea may be useful to others.

The knob is attached to a shaft, on the shaft is a friction collar - tight enough to operate the micro switches but loose enough to slip once the micro switch is reached. A cam operates another microswitch to allow a count of the number of turns.

The programme simply monitors the left right switch to decide direction and then counts the turns.

I needed to know the direction of turning and how many times the knob is turned.

I have, after some experimentation, come up with the attached which seems to work OK in my lash up at present and now moves to the better engineered stage to improve the looks. The idea may be useful to others.

The knob is attached to a shaft, on the shaft is a friction collar - tight enough to operate the micro switches but loose enough to slip once the micro switch is reached. A cam operates another microswitch to allow a count of the number of turns.

The programme simply monitors the left right switch to decide direction and then counts the turns.

Attachments

-

142.6 KB Views: 230