Hi,

So non-PWM with analog dimming and PWM with PWM Dimming. That is how I read it.

Not quite, IMHO. "Analogue Dimming" would involve a large power dissipation in the LDD-1500, which I don't believe such a small device could tolerate. At the extreme, the specification mentions a maximum input voltage of 36v and an output of 1 Amp into a 2 volt diode. That implies an "analogue" dissipation of 34 watts in the LDD-1500!

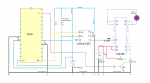

My reading of the data sheet is that the device has four "modes": OFF , ON , internal PWM (analogue dimming) and "brute force" (ON/OFF) dimming (but still using internal PWM to reduce the power dissipation). So, as Goeytex says, the transistors Q1 and Q2 (and the use of a DAC-derived analogue input) seems completely unnecessary.

This isn't the place for a complete "tutorial" on PWM, but IMHO this thread contains (at least) three fundamental misunderstandings: Firstly, even a humble PICaxe can generate PWM frequencies between less than 100 Hz to over 1 MHz, that's a ratio of over 10,000 : 1 and most electronics components will behave very differently over that range (compare with what you might be able to do in one second against 3 hours!). Secondly, there is the difference between the "Interface" specification and the "Output" Operation/Mode: For example, a modeller's "Servo" which uses a Width-Modulated Pulse Interface, but has an Analogue (position) Output. Finally, there is the absolutely fundamental difference of whether the (PWM) Output

Load is Resistive or Inductive; But note that there may be (Inductive or Resistive) Low-Pass filters "hidden" in modules such as the LDD-1500.

Firstly, consider simple LED dimming with a resistive load; for example two 3 volt LEDs in series with a 60 ohm resistor across 12 volts: A current of 100 mA will flow, giving a power of 600 mW in the diodes (together) and another 600 mW dissipation in the resistor, an "efficiency" of 50%. Switch that on and off rapidly with a 50% duty cycle "PWM" (at almost any frequency) and the

average current will fall to 50mA, with halved (average) dissipation in the LEDs and Resistor. The peak current is still 100 mA but the (human) eye will see a lower brightness because it averages the brightness (i.e. it is a low-pass filter).

However an inductive load is completely different: The PWM frequency becomes very important; at 100 Hz most (small) inductors will just behave like a resistor (since they are wound with resistive copper wire), whilst at 1 MHz they may virtually "look" like an open circuit. But at the "design" frequency, when the (PWM) Output Voltage is "High", the current gradually increases in the circuit; there must still be 6 volts across the LEDs, so also 6 volts across the inductor, but it doesn't "dissipate" (much) power; instead it

stores the energy in its magnetic field. Then during the PWM OFF period, the current continues to flow (via the essential "flywheel" diode), gradually reducing. Nearly all the energy is recovered from the inductor and applied to the LEDs (since the voltage across the inductor is now reversed). There can still be an average 50 mA flowing in the LEDs, but only 25 mA average (50mA for half of the time) from the supply, thus almost 100% efficiency.

But the user doesn't need to "know" about all of this (which is the basic principle of any PWM power supply), because the inductor is hidden in the module: with correctly chosen components the output can just "look" like a constant voltage and current (which effectively it is). The same can apply to the "Analogue" input, a simple Low-Pass filter can be inserted to convert (i.e. average) the PICaxe's PWM signal to create an analogue input. Then the (essential) PWM Modulator inside the LDD-1500 generates its own "internal" PWM signal at a very high frequency (the data sheet says 1 MHz) to permit it to use small inductance and capacitance values.

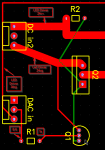

Finally, an observation on the "DAC" input to the PCB: It appears to have an Analogue signal input (although it's driving a digital amplifier !) and an "Enable" input, but

NO Earth ! An analogue input should

always have a partner Earth (even if it may be later decided that it's necessary to break an "Earth Loop" for good "audio" quality

).

Cheers, Alan.