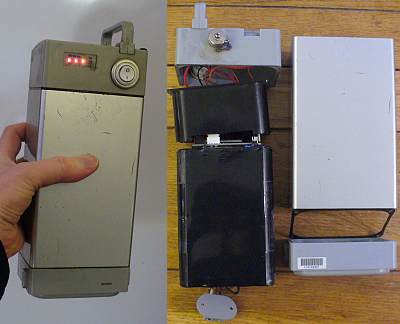

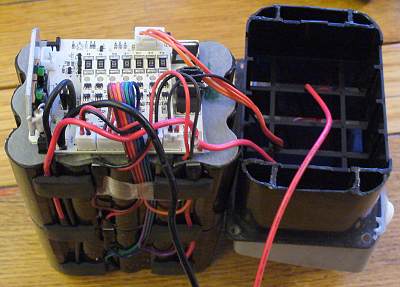

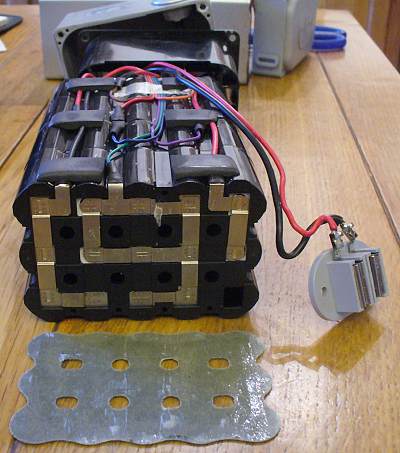

In a few weeks time I'll be ordering a large batch of 18650 sized li-ion cells from China because I intend to re-cell one of my ebike batteries which has 28 of these cells inside, the price of a new ebike battery is £329, but 28x 3800mAH cells starts at about £50 from China.

I'll be ordering more than I eventually need because I don't want to blindly drop in 28 3800mAH li-ion cells into a pack (albeit with a strong aluminium case) without testing them beforehand, and to find out if there are any bad cells in the order and also try to match minor capacitiy differences (the pack is made up of 7 sets of 4 in parallel), I intend to build something to test the capacity of the cells, powered by a Picaxe with LCD screen, control buttons etc.

My main query here is regarding the discharge capacity test of the device, the DIY battery capacity tester here - http://www.instructables.com/id/Arduino-True-Battery-Capacity-Tester-Li-IonNiMH/ - uses a 10 watt 2.2ohm resistor as the load.

Does that mean the resistor will put a 10 watt load onto the cell no matter what the voltage of it is?

The final device will have charging capabilities through use of commercial chargers, and the ability to test more than once cell at the same time because running the test on 28+ cells will take quite a time.

Also, is there anything I should be looking into/be wary of when dealing with charging/discharging li-ion cells? I am aware of the dangers of over/under charging & shortcircuiting them.

I'll be ordering more than I eventually need because I don't want to blindly drop in 28 3800mAH li-ion cells into a pack (albeit with a strong aluminium case) without testing them beforehand, and to find out if there are any bad cells in the order and also try to match minor capacitiy differences (the pack is made up of 7 sets of 4 in parallel), I intend to build something to test the capacity of the cells, powered by a Picaxe with LCD screen, control buttons etc.

My main query here is regarding the discharge capacity test of the device, the DIY battery capacity tester here - http://www.instructables.com/id/Arduino-True-Battery-Capacity-Tester-Li-IonNiMH/ - uses a 10 watt 2.2ohm resistor as the load.

Does that mean the resistor will put a 10 watt load onto the cell no matter what the voltage of it is?

The final device will have charging capabilities through use of commercial chargers, and the ability to test more than once cell at the same time because running the test on 28+ cells will take quite a time.

Also, is there anything I should be looking into/be wary of when dealing with charging/discharging li-ion cells? I am aware of the dangers of over/under charging & shortcircuiting them.

Last edited: