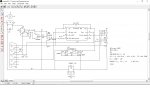

It might be time to specify exactly what the project is and how it is intended to work, what sort of range it has to cover, and how accurately.If you intend to use the same Picaxe measure the flywheel velocity and to also control a Brushless DC motor with precision it may be

somewhat tricky due to the processor overhead.

Generating fixed frequency pulse trains can be done by tweaking PAUSEUS values but the values are usually hand-tuned by trial and error while observing the outputs on a scope or logic analyser.

One would probably have to come up with some sort of look-up table and means of calculating the values if one wanted variable output frequencies. I am not sure how best that would be done or how good the results would be.

Adding something into the mix to allow that to be adjusted from something else would also be a challenge as that itself will affect the timing and values needed. As Goeytex says; could be tricky on a single PICAXE.

It could still be tricky with two PICAXE's, one indicating what is required, the other actually delivering that. One would need to find a way of getting data into the second and having it used without disrupting what it's doing, it's timing in any way. There are some possibilities but they would work best with byte values, not anything larger.