Jeremy Harris

Senior Member

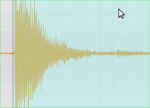

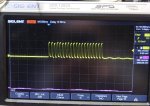

Yes, the frequency and number of pulses will have to be a compromise between the pipe diameter and the minimum expected water depth and the ease of filtering out the expected echo return. The burst length always needs to be shorter than the round trip time-of-flight time for the shallowest depth, in my case around 8m (4m depth x 2). I'm not sure yet, but think there's probably an advantage in having a specific frequency "ping", rather than just a pulse, if only to make detection easier.

In theory, I could increase the frequency of the burst above 300Hz, I'm sure. As long as the wavelength remains significantly longer than the well liner inside diameter, then there should be almost no interference from wall reflections. With my 119mm liner inside diameter, that's a frequency of just under 2.8 kHz. I chose 300 Hz as it's roughly 1/10 of that frequency, to be on the ultra-safe side, but I could probably usefully increase the frequency of the tone burst to around 1 kHz, and still remain reasonably free from wall reflections.

1 KHz is 0.33m per cycle, so 10 cycles would be 3.33m, which is less that half the total distance for the round trip down and back to the water surface at the shallowest depth I'm likely to ever get.

I think some more experiments are needed, as increasing the frequency would definitely improve the efficiency of the small waterproof speaker a fair bit. Be able to use a burst of 1 kHz as the pulse would also make the filtering simpler and reduce the length of the pipe that I intend to use a as an acoustic filter at the well head.

In theory, I could increase the frequency of the burst above 300Hz, I'm sure. As long as the wavelength remains significantly longer than the well liner inside diameter, then there should be almost no interference from wall reflections. With my 119mm liner inside diameter, that's a frequency of just under 2.8 kHz. I chose 300 Hz as it's roughly 1/10 of that frequency, to be on the ultra-safe side, but I could probably usefully increase the frequency of the tone burst to around 1 kHz, and still remain reasonably free from wall reflections.

1 KHz is 0.33m per cycle, so 10 cycles would be 3.33m, which is less that half the total distance for the round trip down and back to the water surface at the shallowest depth I'm likely to ever get.

I think some more experiments are needed, as increasing the frequency would definitely improve the efficiency of the small waterproof speaker a fair bit. Be able to use a burst of 1 kHz as the pulse would also make the filtering simpler and reduce the length of the pipe that I intend to use a as an acoustic filter at the well head.