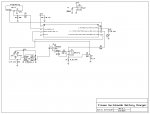

I'm getting strange behavior with this NiMH battery charger circuit where it will start charge even with no battery inserted. It worked fine for months but a couple days ago started with this problem. I haven't yet removed the circuit board from the charger to debug and see what the ADC is doing, but I've seen similar problems and had it work by simply replacing the Picaxe. The supply voltage is supposed to be 5V but I have seen about 5.2V from the power supply. Either that is causing damage over time, or perhaps the battery positive connection to the ADC pin needs something to remove possible spikes. I have the 22K resistor there for that purpose, but that may not be working the way I think.

Code:

Code:

Code:

init:

setfreq m32

symbol battery = c.1

symbol currentsns = c.4

symbol pwmoutput = c.2

symbol led = c.0

symbol current = w0

symbol currentcount = w1

symbol currentsum = w2

symbol dutycyc = w3

symbol voltcount = w4

symbol volts = w5

symbol voltavg1 = w6

symbol voltsum = w7

symbol peakvolt = w8

symbol deltapeak = w9

symbol modulus = w10

symbol highvolt = w11

dutycyc = 0

current = 0

currentcount = 0

currentsum = 0

voltcount = 0

volts = 0

voltavg1 = 0

voltsum = 0

peakvolt = 0

deltapeak = 0

pwmout pwmoutput, 200, dutycyc

low led

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

toggle led

pause 1000

pause 16000

start:

gosub battdetect

main:

for voltcount = 0 to 199

modulus = voltcount // 5

if modulus = 0 then

toggle led

endif

current = 0

gosub getcurrent

if current < 125 then

dutycyc = dutycyc + 1 max 900

endif

if current > 125 then

dutycyc = dutycyc min 1 - 1

endif

pwmduty pwmoutput, dutycyc

next voltcount

gosub getvolts

if volts < 100 then init

if volts > peakvolt then

peakvolt = volts

deltapeak = 0

endif

if volts <= peakvolt then

inc deltapeak

endif

if deltapeak > 5 then endchg

debug

goto main

getcurrent:

fvrsetup FVR2048 ; set to 2.048V

adcconfig %011

current = 0

currentcount = 0

currentsum = 0

for currentcount = 0 to 49

pause 7

current = 0

readadc10 currentsns, current

currentsum = current + currentsum

next currentcount

current = currentsum / 50

return

getvolts:

fvrsetup FVR4096 ; set to 4.096V

adcconfig %011

volts = 0

voltsum = 0

voltavg1 = 0

pwmduty pwmoutput, 0

pause 8000

for voltavg1 = 0 to 19

readadc10 battery, volts

voltsum = volts + voltsum

next voltavg1

volts = voltsum / 20

pwmduty pwmoutput, dutycyc

return

battdetect:

dutycyc = 500

pwmduty pwmoutput, dutycyc

gosub getvolts

if volts < 100 then start

dutycyc = 0

return

endchg:

pwmduty pwmoutput, 5

high led

pause 8000

gosub getvolts

if volts < 100 then

goto init

endif

pwmduty pwmoutput, 0

pause 24000

debug

goto endchg