scamanderriver

Member

Hi I'm looking for advice

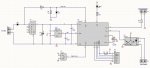

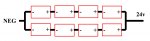

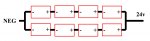

I have 2 solar battery banks that consist of (1) 8 x 6v batteries in series/parallel totaling 24v and (2) 12 x 2v batteries in series/parallel totaling 12v

I would like to monitor the voltage each battery independently

The power supply to the Picaxe chip will share the same negative as the battery banks

To measure the voltage of each battery accurately I think I need to access the Neg and Pos of each independently

I have thought of 2 possible ways but I am not really happy with either.

1. use the common Neg and read the +ve of each battery in sequence, starting from the NEG end and then subtracting the previous battery value to give the current battery value i.e bat1 = bat1, bat2 = bat2-bat1 etc. one issue is that the last 2 batteries will be seen as one.

2. Using many Picaxe 8M's as slaves with a totally separate power supply for each on each battery and then sending the result to a master picaxe chip.

I think this is expensive, cumbersome, not very elegant.

Being an electronic novice I don't really have a clue how to do this properly and would be grateful for a kick start.

Can anyone please offer me advice.

Cheers

Paul

I have 2 solar battery banks that consist of (1) 8 x 6v batteries in series/parallel totaling 24v and (2) 12 x 2v batteries in series/parallel totaling 12v

I would like to monitor the voltage each battery independently

The power supply to the Picaxe chip will share the same negative as the battery banks

To measure the voltage of each battery accurately I think I need to access the Neg and Pos of each independently

I have thought of 2 possible ways but I am not really happy with either.

1. use the common Neg and read the +ve of each battery in sequence, starting from the NEG end and then subtracting the previous battery value to give the current battery value i.e bat1 = bat1, bat2 = bat2-bat1 etc. one issue is that the last 2 batteries will be seen as one.

2. Using many Picaxe 8M's as slaves with a totally separate power supply for each on each battery and then sending the result to a master picaxe chip.

I think this is expensive, cumbersome, not very elegant.

Being an electronic novice I don't really have a clue how to do this properly and would be grateful for a kick start.

Can anyone please offer me advice.

Cheers

Paul