Hemi345

Senior Member

About five or so years ago I built a Humidistat based on a PICAXE 18M2 on perf board. You can find that project HERE. A couple years ago I decided I wanted to start on version 2 so I've been taking my time thinking about everything I wanted to do with it. About a year ago I noticed the operating voltage it was reporting/logging was slowly creeping up. After power outages, I noticed the voltage would be back to 4.9-5V but about six months ago it said running at 8.9VDC. I just figured there must be something wrong with the voltage reference and dismissed it until a massive hail storm took out the little DS18B20 on the side of the house. While repairing that, I measured the voltage with my multimeter and sure enough, it was nearly 9V! Amazingly everything was still running but I knew I was on borrowed time so I've been putting more effort into version 2 that will have move functionality and features.

Requirements for the new project:

1) Control the whole house humidifier based on outdoor temperature and home humidity level - like version 1 did

2) Log when the HVAC turns on/off - be interesting to see how many times it runs per day and for how long

3) Log the indoor humidity level, outdoor, return air, supply air temperatures - really curious what the supply air temp is while the furnace/AC is running

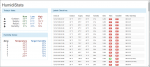

4) Transmit/upload all details wirelessly to my IoT website - because graphs are fun

5) Incorporate a cute little OLED display and buttons on the device for local changes - switchin' things up from the two digit seven segment display

6) Bonus points if I automate operating the Summer/Winter damper on the humidifier - a standard size servo and stepper motor are sitting in a box doing nothing, might as well use one of them

Even thought this project isn't finished, I'm going to post here as a build log since the blogs are no more.

Next up, details about the "return air sensor" module.

Requirements for the new project:

1) Control the whole house humidifier based on outdoor temperature and home humidity level - like version 1 did

2) Log when the HVAC turns on/off - be interesting to see how many times it runs per day and for how long

3) Log the indoor humidity level, outdoor, return air, supply air temperatures - really curious what the supply air temp is while the furnace/AC is running

4) Transmit/upload all details wirelessly to my IoT website - because graphs are fun

5) Incorporate a cute little OLED display and buttons on the device for local changes - switchin' things up from the two digit seven segment display

6) Bonus points if I automate operating the Summer/Winter damper on the humidifier - a standard size servo and stepper motor are sitting in a box doing nothing, might as well use one of them

Even thought this project isn't finished, I'm going to post here as a build log since the blogs are no more.

Next up, details about the "return air sensor" module.