dillond666

New Member

Hi,

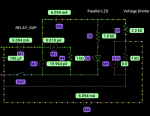

I am aware that there is a maximum input impedance that should not be exceeded when doing ADC (2.5k?) But wish to measure the voltage of a 12v battery using ADC10.

Could I use higher resistances in my voltage divider if I put a capacitor across the resistor that the Picaxe is measuring the voltage across? Would this capacitor lower the

impedance at the Picaxe input?

Any advice gratefully received.

Derek

I am aware that there is a maximum input impedance that should not be exceeded when doing ADC (2.5k?) But wish to measure the voltage of a 12v battery using ADC10.

Could I use higher resistances in my voltage divider if I put a capacitor across the resistor that the Picaxe is measuring the voltage across? Would this capacitor lower the

impedance at the Picaxe input?

Any advice gratefully received.

Derek