Andres Rodriguez

New Member

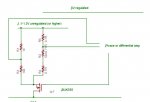

I need to determine the hfe (gain) value of the transistors that will drive the 1 Amp load. I tried to find the maximum amps from the output pins. The formula I'm using is:

Minimum transistor gain (hfe)=5*(load/max pin current).

I tried to find the max pin current from the 12F683 datasheet and (maybe I did not look in the right places) could not find it.

Any help or suggestions will be amply rewarded.

Thank you in advance

Andrés Rodríguez

Minimum transistor gain (hfe)=5*(load/max pin current).

I tried to find the max pin current from the 12F683 datasheet and (maybe I did not look in the right places) could not find it.

Any help or suggestions will be amply rewarded.

Thank you in advance

Andrés Rodríguez

Attachments

-

4 KB Views: 68

Last edited: