fritz42_male

Senior Member

Hi all,

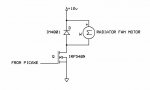

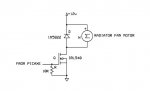

Just a quickie. I need some motor control of a car radiator fan. 12V and approx. 2-3A current. I don't really have any problems with the Picaxe side but can anyone tell me if I would have any issues with the following driver circuit?

I only need to control the speed in one direction. The Picaxe would run off a clean 5V supply with only a common ground.

Thanks

Just a quickie. I need some motor control of a car radiator fan. 12V and approx. 2-3A current. I don't really have any problems with the Picaxe side but can anyone tell me if I would have any issues with the following driver circuit?

I only need to control the speed in one direction. The Picaxe would run off a clean 5V supply with only a common ground.

Thanks

Attachments

-

16.8 KB Views: 141